Description

Food products dosing and weighing for the farming industry

Our client, a food producer specialized in food-preparation for breeding livestock wanted to modernize his dosing system.

The ergonomics and tracability of the control software would allow both the formulation laboratory and the operators to work simultaneously on the dosing system.

Tracability of the dosed ingredients would allow to follow each component, each batch and each supplier.

The operators registration had to complete the tracability (turnover).

The plant working in continuous flow, could only stop for short maintenance operations, so the modernization operation had to follow a rigorous schedule.

Weighing and dosing constraints of food products in the farming industry

The dosing-weighing system was interconected with a PLC and an ERP, so the continuity of these links and the integrity of the data had to be guaranteed when they switch to new equipment.

Until now, management and tracability were carried out on paper and had to be saved on a numeric support.

The dosing system could not be shut down for a long period, to guarantee a fast restart.

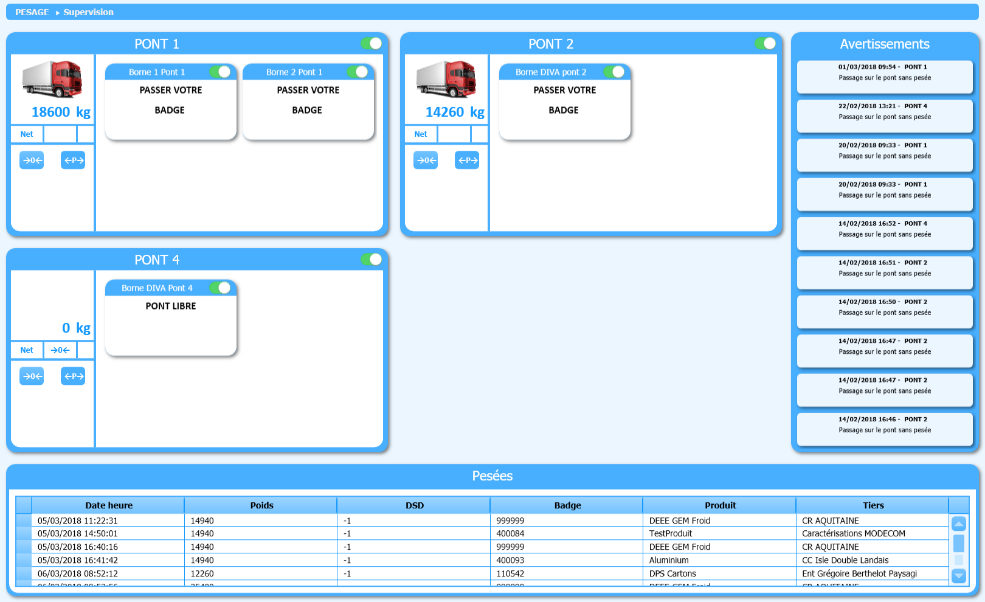

Diagram of the entire solution of weighing and dosing instruments for the farming industry

Weighing equipment installed on-site:

- IDE250 Weighing indicator

- RP15M Remote display

- Doseview weighing-dosing management software

Added value of our solution:

Tracability and real-time reports allow a dynamic management of production quality.

The multi-user mode allowed 10% time saving (we program and realize the formulas at the same time).

The modernization of the weighing system was carried out in 48 hours without any lost of information.